Commissioning, qualification and maintenance

시운전, 검증 및 유지보수

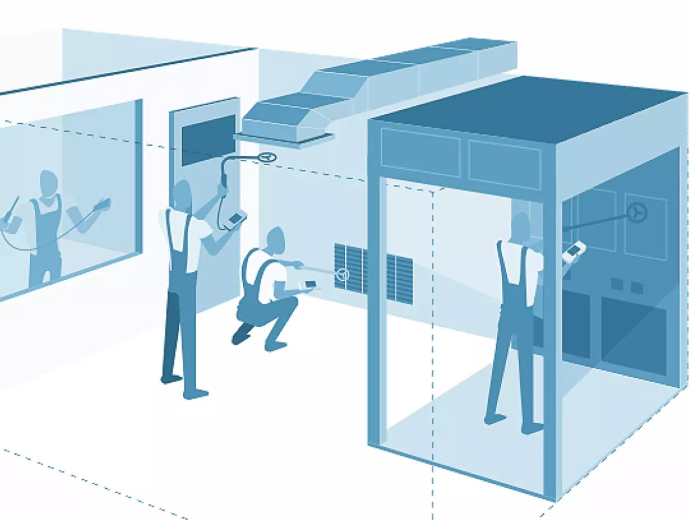

Aeraulic systems require regular intervention by HVAC professionals, starting

with their fine-tuning. During this first stage, developers ensure that all

system components are designed, installed, tested and used so as to comply

with the operational specifications set by the project managers and their

client. These essential checks ensure that the aeraulic system operates

with optimal efficiency from the start.

Several periodic interventions are also necessary: from regulatory inspections

to maintenance operations on the entire aeraulic system, this work involves

the control of all air parameters, so as to detect the slightest weakness or

component defect, starting by the clogging of air filters, the most common

phenomenon.

Each of these interventions involves the use of high-end portable measuring

devices. Sauermann instruments meet these professional requirements

while remaining easy and quick to use to allow technicians and engineers to focus on their core skills, without wasting time.

Pressure measurement at filters is particularly important to preserve fans and save energy.

- MULTIFUNCTION

- AIR SPEED AND FLOW

- DIFFERENTIAL PRESSURE

- TEMPERATURE AND HUMIDITY

- AIR SPEED AND FLOW

- CO2

- TACHYMETRY

MULTIFUNCTION

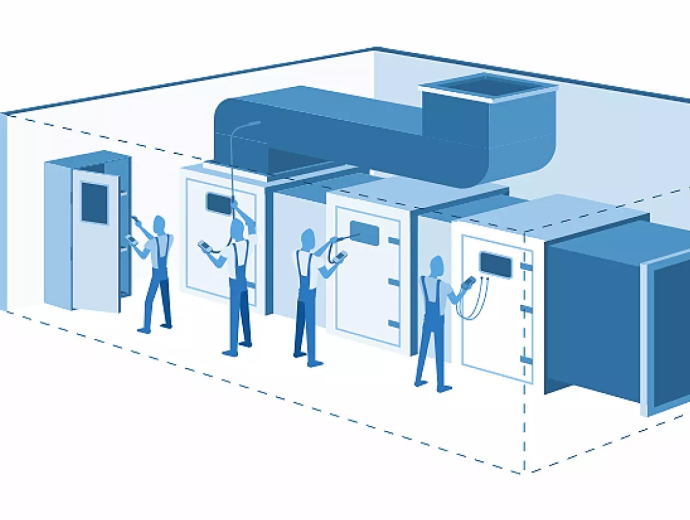

Control of aeraulic systems requires the

measurement of several air parameters:

temperature, pressure, air velocity and flow,

hygrometry, CO2 rate, etc. This is the reason why

multifunctional portable measuring devices are

the preferred tools for this type of intervention.

Sauermann specializes in the manufacture of this

type of high-end instrument, offering cutting-edge

measurement precision to carry out compliance

checks with regulations and recommendations

on indoor air quality in residential, tertiary and industrial buildings.

Sauermann's multifunction portable devices are

among the most advanced on the market for

commissioning, testing, balancing and

maintenance activities. They are also designed to

optimize the efficiency of professionals: flawless

reliability, speed and ease of use. Their modular

design makes it possible to add the necessary

probes to combine a tailor-made solution, the

calibration of which is COFRAC ISO 17025:2017

certified within the Sauermann laboratories.

AIR SPEED

AND FLOW

To ensure good indoor air quality in tertiary and

ERP buildings, Sauermann quickly became aware

of the crucial importance of measuring flow, and

especially its corollary: the rate of

renewal of indoor air ( TRA). This is why the DBM 620 was

specially designed: to simplify the calculation of

the TRA thanks to the mobile application of the

DBM 620 balometer. The measurement of air flow

rates is particularly crucial to ensure a sufficiently

high and optimized air renewal rate. terms

of energy consumption.

“The balometer is the most versatile and effective

portable instrument for measuring mouth flow”

The air renewal rate is particularly important to

ensure the constant sanitation of indoor air by

injecting filtered air into a room. This renewal is

the most effective way to reduce the

concentration of pollutants such as volatile

organic compounds (VOCs), bacteria, viruses, or

dust. Measuring TRA is therefore particularly

important to ensure that the air inside a confined

space is clean and healthy. The balometer is the

most versatile and effective portable instrument

for

measuring flow: it easily adapts to any type of air

vent, for blowing or extraction, and offers greater

measurement accuracy than any other solution.

DIFFERENTIAL

PRESSURE

Measuring differential pressure across an air filter

is the most common maintenance intervention,

and one of the most important. Regularly

replacing clogged filters helps improve air quality

and flow rates while saving energy. A new filter

actually causes much less pressure loss than a

clogged filter, and will not contaminate the air

passing through it.

“The most common maintenance intervention,

and one of the most important”

TEMPERATURE

AND HUMIDITY

Temperature and humidity are among the basic

parameters of indoor air management. They

condition many other elements of the ventilation

chain, starting with the heating and air

conditioning settings.

These two parameters can also have significant

consequences on the health and comfort of the

occupants of a tertiary building, and on the

durability of certain materials, mainly to avoid

mold. This is particularly why these parameters

are measured both within the ventilation ducts

and in the ambient air of the living spaces of a

building.

“Certain specific tertiary environments require

very fine management of temperature and

humidity, such as server farms”

Certain specific tertiary environments also

require very fine management of temperature and

humidity, such as server farms (data centers) and

certain similar technological premises.

AIR SPEED

AND FLOW

For verification and maintenance interventions,

Sauermann offers portable devices and cones

adapted in different formats to quickly obtain

reliable flow measurements on hydrants. The

Sauermann devices intended for these

measurements are thermo-anemometers, they

therefore make it possible to measure at the same

time the temperature of the air flow in order to

better understand the performance of the aeraulic

system.

Better manage indoor air quality while optimizing

the energy consumption of the ventilation system

Flow measurement is absolutely crucial in indoor

air management. This parameter conditions all of

the building's air conditioning conditions. Its

precise adjustment makes it possible to better

manage indoor air quality while optimizing the

energy consumption of the ventilation

system. The flow rate assessment must also be

carried out on the extraction vents, to check that

the air in the room, loaded with CO2, particles,

chemical or biological compounds and other

pollutants is effectively evacuated.

CO2

The concentration of carbon dioxide in indoor air

is a crucial measure for assessing indoor air

quality. CO2 is the preferred indicator of the

indoor air renewal rate (TRA) for several reasons:

it is very reactive to changes in indoor

atmospheric conditions, it directly takes into

account the number of occupants in a room (each

exhaling from CO2), and it is quick to measure.

“Sauermann instruments are equipped with NDIR

(non-dispersive infrared) type CO2 sensors, the

only ones capable of providing reliable

measurement results for the CO2 level.”

However, reliable CO2 measurement requires the

use of high-end and calibrated devices. This is

why Sauermann instruments are equipped with

NDIR (non-dispersive infrared) type CO2 sensors,

the only ones capable of providing reliable

measurement results for the CO2 level. The

Sauermann AQ 110 portable measuring

instrument is laboratory adjusted and certified to

meet all regulatory requirements for CO2

measurement. It can take one-off measurements,

but also

record measurement campaigns using its

internal memory, to study the evolution of CO2

throughout the day in a room depending on its

occupancy. These campaigns make it possible to

better target the necessary TRA by adjusting the

air flow rates of the ventilation system.

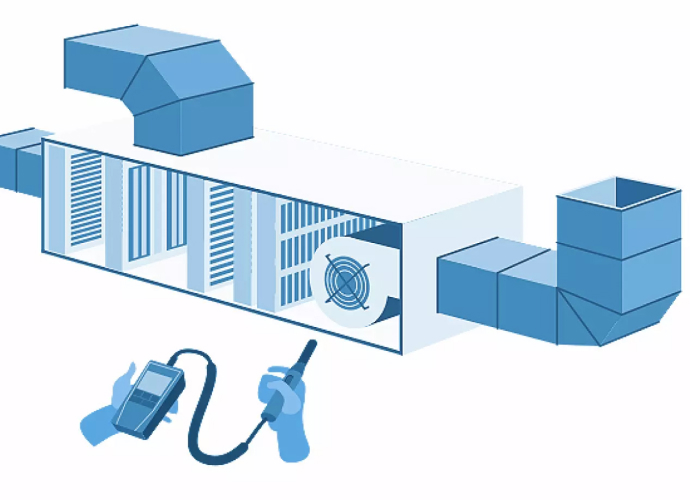

TACHYMETRY

Tachometers provide precise measurement of the

actual rotation speed of a fan within an air

handling unit. These elements are mechanically

subject to wear, and regularly checking their

performance helps prevent breakdowns that lead

to operational interruptions, or worse, to material

damage in sensitive technological premises such

as server farms.

Prevent outages that lead to operational

interruptions, or worse, material damage in

sensitive technology premises.

The Sauermann CT 110 tachometer allows easy

and ultra-reliable measurements of these

parameters, thanks to a very handy remote probe,

operating in optical or contact mode, all delivered

with a calibration certificate.

PRODUCTS AND ACCESSORIES

-

AMI 310

AMI 310KIMO AMI 310 휴대용 다기능 측정기 입니다. 풍속, 풍량 (베인 프로브 및 열선), 압력, 온도 (PT100 및 써모커플), 습도, 공기질 (CO/CO₂),회전 속도계를 포함한 여러 항목을 동시에 측정합니다. 풍속프로브 (유/무선, 텔레스코픽 타입 선택) 모델명 형식 풍속 범위 SH14 / SHT14 ø14 mm 베인프로브 0 ~ 25 m/s SH70 / SHT70 ø70 mm 베인프로브 0.5 ~ 35 m/s SH100 / SHT100 ø100 mm 베인프로브 0.5 ~ 35 m/s SFC300 / SFC900 열선프로브 0.15 ~ 30 m/s 온습도프로브 (유/무선 선택) 모델명 온도 습도 SHR110 -20 ~ 80 ℃ 0 ~100 %RH SHR300 -40 ~ 180 ℃ 0 ~100 %RH 대기압 모델명 온도 차압 (대기압) 습도 MCC 0 ~ +50 ℃ 800 ~ 1,100 hPa 5 ~ 95 %RH RPM(타코미터) 모델명 접촉식 비접촉식 STA 30 ~ 3,000 rpm 60 ~60,000 rpm 공기질모델명 CO CO₂ 온도 습도 SCO 110 0 ~ 500 ppm -20 ~ +80 ℃ SCO 112 0 ~ 5,000 ppm -20 ~ +80 ℃ SCOH 112 0 ~ 5,000 ppm -20 ~ +80 ℃ 5 ~ 95 %RH 조도 모델명 조도 SLU 0 ~ 150,000 LUX 온도 모델명 온도 M4TC 교체형 4채널 써머커플 모듈 K: -200 ~ +1300 °C J: -100 ~ +750 °C T: -200 ~ +400 °C S: 0 ~ +1760 °C N: -200 ~ +1300 °C MCU 교체형 U coefficient 모듈 -20 ~ +1,300 °C

Read More -

MP 210

MP 210KIMO MP210 휴대용 다기능 압력계입니다. ±500 Pa, ±2,500 Pa, ±10,000 Pa, ±500 mbar, ±2,000 mbar 압력, 풍속, 풍량, 온도, 회전속도, 가스 누출 및 일산화탄소 등 다양한 프로브와 호환됩니다. (최대 6개 동시 측정) 압력 - 5가지 교체형 모듈 MPR 500 0 ~ ±500 Pa MPR 2500 0 ~ ±2500 Pa MPR 10000 0 ~ ±10000 Pa MPR 500M 0 ~±500 mbar MPR 2000M 0 ~ ±2000 mbar 풍속프로브 (유/무선, 텔레스코픽 타입 선택) 모델명 형식 풍속 풍량 온도 SH14 / SHT14 φ14 mm 베인프로브 0 ~ 25 m/s 0 ~ 99,999 m³/s -20 ~ 80 ℃ SH70 / SHT70 φ70 mm 베인프로브 0.5 ~ 35 m/s SH100 / SHT100 φ100 mm 베인프로브 0.5 ~ 35 m/s SFC300 / SFC900 열선프로브 0.15 ~ 30 m/s 온습도프로브 (유/무선 선택) 모델명 온도 습도 SHR110 -20 ~ 80 ℃ 0 ~100 %RH SHR300 -40 ~ 180 ℃ 0 ~100 %RH 대기압 모델명 온도 차압 (대기압) 습도 MCC 0 ~ +50 ℃ 800 ~ 1,100 hPa 5 ~ 95 %RH RPM(타코미터) 모델명 접촉식 비접촉식 STA 30 ~ 3,000 rpm 60 ~60,000 rpm 공기질 모델명 CO CO₂ 온도 습도 SCO 110 0 ~ 500 ppm -20 ~ +80 ℃ SCO 112 0 ~ 5,000 ppm -20 ~ +80 ℃ SCOH 112 0 ~ 5,000 ppm -20 ~ +80 ℃ 5 ~ 95 %RH 조도 모델명 조도 SLU 0 ~ 150,000 LUX 온도 모델명 온도 M4TC 교체형 4채널 써머커플 모듈 K: -200 ~ +1300 °C J: -100 ~ +750 °C T: -200 ~ +400 °C S: 0 ~ +1760 °C N: -200 ~ +1300 °C MCU 교체형 U coefficient 모듈 -20 ~ +1,300 °C

Read More -

VT 210

VT 210KIMO VT210 휴대용 풍속 풍량 온습도계 입니다. 베인풍속 0 ~ 35 m/s, 열선풍속 0.15~30 m/s, 온/습도 풍속 다기능환기 시스템의 제어를 위해 설계되어 덕트의 풍속, 풍량 및 온도를 측정할 수 있습니다.풍속프로브 (유/무선, 텔레스코픽 타입 선택) 모델명 형식 풍속 범위 SH14 / SHT14 ∅14 mm 베인프로브 0 ~ 25 m/s SH70 / SHT70 ∅70 mm 베인프로브 0.5 ~ 35 m/s SH100 / SHT100 ∅100 mm 베인프로브 0.5 ~ 35 m/s SFC300 / SFC900 열선프로브 0.15 ~ 30 m/s 온습도프로브 (유/무선 선택) 모델명 온도 습도 SHR110 -20 ~ 80 ℃ 0 ~100 %RH SHR300 -40 ~ 180 ℃ 0 ~100 %RH 대기압 모델명 온도 차압 (대기압) 습도 MCC 0 ~ +50 ℃ 800 ~ 1,100 hPa 5 ~ 95 %RH RPM(타코미터) 모델명 접촉식 비접촉식 STA 30 ~ 3,000 rpm 60 ~60,000 rpm 조도 모델명 조도 SLU 0 ~ 150,000 LUX 온도 모델명 온도 M4TC K: -200 ~ +1300 °C J: -100 ~ +750 °C T: -200 ~ +400 °C S: 0 ~ +1760 °C N: -200 ~ +1300 °C

Read More -

HQ 210

HQ 210KIMO HQ210 다기능 휴대용 공기질 측정장비 입니다. 교체형 프로브에 따른 측정범위 입니다. 온습도프로브 (유/무선 선택) SHR110 -20 ~ 80 ℃, 0 ~100 %RH SHR300 -40 ~ 180 ℃, 0 ~100 %RH 무지향성 기류측정기 SOM900 0.00~5.00 m/s, 5~95 %RH, -20~80 ℃ 실내공기질 SCOH112 -20 ~ 80 ℃, 0 ~5000 ppm, 0 ~ 100 %RHSCO110 0 ~ 500 ℃, 0 ~ 500 ppm 교체형 대기압 모듈MCC 0 ~ +50 ℃, 800 ~ 1,100 hPa, 5 ~ 95 %RH

Read More -

MP 110 / 111 / 112 / 115

MP 110 / 111 / 112 / 115KIMO의 MP 110 / 111 / 112 / 115은 휴대용 압력(차압)계 입니다. 클린룸 환경에서의 정밀한 차압 측정을 지원하며, 휴대하기 편리한 디자인을 갖추고 있습니다. 신뢰성이 있는 성능으로 인정 받고 있으며, 다양한 환경에서 사용이 가능한 장비 입니다.

Read More -

TK 61, TK 62

TK 61, TK 62KIMO의 TK 61/62 써모커플 디지털 온도계입니다. 다양한 열전대를 사용하여 공기 온도를 정확하게 측정하도록 설계되었습니다. 프로브는 포함되지 않으며 별도 판매됩니다.

Read More -

KIRAY 100

KIRAY 100KIMO의 적외선 온도계 KIRAY100 입니다. 측정범위 -50 ~ +800 °C 입니다. 듀얼 레이저 조준기가 장착되어 “비접촉" 기술을 사용하는 장점과 함께 모든 온도를 진단, 검사 및 확인하는 핵심 장비입니다. 적외선 온도계는 위험하거나 접근하기 어려운 뜨거운 물체의 표면 온도를 측정합니다.

Read More -

HD 110

HD 110KIMO의 휴대용 온습도계 HD 110 입니다. 센서 일체형 케이블 타입으로 상대 습도, 온도 및 이슬점을 측정합니다.

Read More

-

DBM 620

DBM 620Sauermann의 DBM 620은 새롭게 디자인된 공기 유량계 입니다. 주로 공기 통풍구에서 직접 공기량을 효율적으로 판독하는데 사용되는 다목적 전자 공기 균형 장비입니다.

Read More -

LV 110 / LV 111 / LV 117

LV 110 / LV 111 / LV 117KIMO의 LV 110 / 111 / 117은 휴대용 베인(바람개비)형 풍속계 입니다. 베인 프로브를 이용하여 풍속과 풍량, 온도를 함께 측정할 수 있습니다. 바람개비 형태 프로브의 직경은 100 mm, 70 mm, 14 mm로 모델명에 따라 다릅니다. 조건에 알맞은 제품 선택으로 손쉽게 정확한 풍속과 풍량을 측정할 수 있습니다.

Read More -

VT 110 / VT 115

VT 110 / VT 115KIMO VT 110 / 115 열선 풍속계 입니다. 풍속 0.15 ~ 30 m/s, 풍량 0 ~ 99999 m3/h, 온도 0 ~ 50 °C 하위 모델인 VT50의 기능에 풍량을 표시하는 기능이 추가되었습니다. 열선 프로브를 이용한 공기 흐름, 풍속 및 온도를 측정하는 데 적합합니다. VT 115는 90 ° 직각으로 굽혀지며 최대 1미터까지 연장 가능한 텔레스코픽 타입입니다.

Read More -

AQ 110

AQ 110AQ 110은 주변 공기에 존재하는 이산화탄소(CO2) 농도를 측정합니다.

Read More -

CT 110

CT 110CT 110 타코미터는 광학 또는 접촉 연결로 축, 디스크 또는 모터의 RPM을 측정합니다.

Read More -

열선 풍속 프로브 (SFC 300 / SFC 900 / SFC 900GN / SFC 300 S)

열선 풍속 프로브 (SFC 300 / SFC 900 / SFC 900GN / SFC 300 S)KImo 휴대용 열선 풍속 풍량 측정 프로브 입니다.

Read More -

바람개비 (베인) 풍속 프로브 (SH 14 / SHT 14 / SH 70 / SHT 70 / SHF 70 / SH 100 / SHT 100 / SHF 100)

바람개비 (베인) 풍속 프로브 (SH 14 / SHT 14 / SH 70 / SHT 70 / SHF 70 / SH 100 / SHT 100 / SHF 100)KIMO의 바람개비 (베인) 프로브로 풍속과 온도를 측정합니다. 바람개비 직경에 따라 다양한 측정범위가 있습니다.

Read More -

공기질 프로브 (SCO 110 / SCO 112 / SCOH 112)

공기질 프로브 (SCO 110 / SCO 112 / SCOH 112)KIMO 공기질 프로브로 CO, CO2, 온도 및 습도 측정에 사용됩니다.

Read More

-

습도 프로브 (SHR 110 / SHRF 110 / SHR 300 / SHRF 300)

습도 프로브 (SHR 110 / SHRF 110 / SHR 300 / SHRF 300)KIMO의 습도 프로브는 습도, 이슬점, 온도 측정에 사용됩니다.

Read More -

써머커플 및 Pt100 온도 프로브

써머커플 및 Pt100 온도 프로브KIMO의 온도 프로브, 다양한 적용이 가능합니다.

Read More -

압력모듈

압력모듈KIMO의 압력 측정모듈은 두 개의 압력 입력과 한 개의 써머커플 입력으로 구성됩니다. 5가지 모델이 사용 가능합니다.

Read More -

L자 형 피토튜브

L자 형 피토튜브L자형 피토튜브는 유체 흐름 속도를 측정하는데 사용됩니다. ANFOR NF SIO 3966 표준에 따라 제작된 다양한 고품질의 L자형 피토관 입니다.

Read More -

.jpg) S자형 피토튜브

S자형 피토튜브S자형 피토튜브는 유체 흐름 속도를 측정하는 데 사용됩니다. ISO 10780 표준을 따라 제작된 고품질의 피토관 입니다.

Read More

EXPERT CORNER

- 비디오

- INsights News

OUR EXPERTISE

-

- More than 800 m2

of laboratories - Our experts ensure the adjustment and

calibration of our measuring instruments.

- More than 800 m2

-

- After-sales service

within our production lines - Our technicians carry out the maintenance

and repair of your devices.

- After-sales service

-

- More than

20 patents filed - Including our oscillating piston technology

for pumps and our folding frame system

for the DBM 620 flow meter.

- More than