Ventilation systems in sensitive environments must be constantly monitored

to ensure optimal management of indoor air. This monitoring consists of

preventing and detecting breakdowns and poor functioning of air conditioning

within a building. Measuring instruments also make it possible to regulate the

entire ventilation system of a building in real time, room by room.

This type of application uses multifunctional sensor-transmitters, or those

specialized in measuring a particular parameter.

This regulation is therefore part of the overall building management system

(Building Management System or BMS). It also operates a computer network

for data acquisition, control and automatic regulation (Supervisory Control

and Data Acquisition systems, SCADA). This type of IT structure also makes

it possible to optimize the energy consumption of the building, by studying

the data collected by our measuring instruments.

This is why Sauermann transmitters benefit from open connectivity, with

standard outputs, both analog and digital. They are designed to provide

maximum flexibility in the topology, structure and configuration of the building management system.

Objective: non-stop and uninterrupted regulation of air parameters, for

perfect management of indoor air and preventive maintenance of the

aeraulic system.

Raising awareness of indoor air quality has become one of the pillars of the

development of the HVACR industry. The impact of the design, control and

maintenance of HVAC systems on the health and well-being of each

individual is known. It also has a direct influence on energy efficiency.

Creating the best indoor air conditions by following specific guidelines is

the primary goal of regulations such as ANSI/ASHRAE 62.1. Through a set

of specific engineering procedures and methods, ANSI/ASHRAE 62.1

provides the tools necessary for the design and management of VAC

systems in non-residential buildings, in order to guarantee optimal air quality.

Continuous analysis of key air parameters through measurements is

an essential element to succeeding in this important challenge. Sauermann

instruments were designed to help you achieve this goal.

- Multifunction sensors

- TEMPERATURE AND HYGROMETRY

- PRESSURE

- AIR SPEED AND FLOW

- CARBON DIOXIDE

MULTIFUNCTION

SENSORS

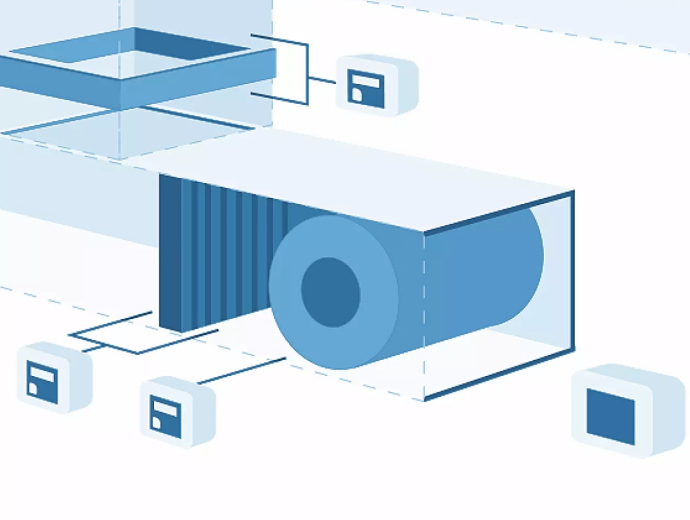

Sauermann's multifunction sensor transmitters

are excellent for the simultaneous measurement

of differential pressure and psychometric

parameters in several scenarios in the VAC sector.

These high-end instruments offer foolproof reliability for constant, long-term

operation.

Differential pressure measurement is particularly

crucial in buildings, because it allows the air

filters of the ventilation network to be

monitored. Some of these filters are HEPA or

ULPA type, to eliminate airborne micro and nano

particles, including bacteria and viruses. They

clog more quickly as their filtering power is high,

which requires constant monitoring to better

anticipate their replacement. This type of

multifunction measuring instrument can also

receive one or more additional probes, to monitor

additional parameters (atmospheric pressure,

temperature/hygrometry, speed/flow, and CO,

CO2 or VOC levels).

TEMPERATURE

AND HUMIDITY

Temperature and relative humidity parameters are

the main indicators of the quality of the indoor

climate of a building. They affect both the health

of occupants and the preservation of products in

storage spaces. The regulation of these

parameters is therefore essential for questions of

health, quality, but also economics. Because the

regulation of these two parameters is the basis of

the energy optimization required by the latest

ecological regulations. It also makes it possible to

detect possible weaknesses in the insulation of a

structure.

For 45 years, Sauermann has been supplying

temperature and humidity sensors whose

reliability is certified ex-factory in our French

laboratories, accredited ISO 17025:2017 for these

two parameters. Sauermann's expertise supports

many establishments in regulating their indoor

air: factories, warehouses, museums, schools,

hospitals, offices, etc.

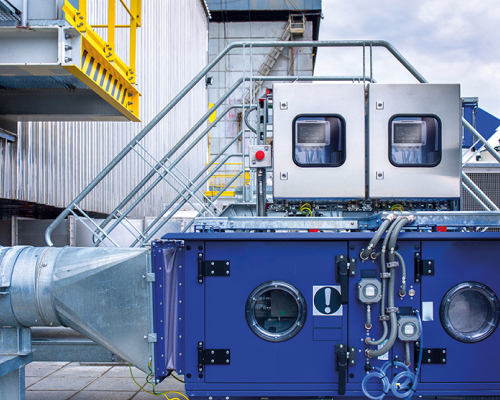

PRESSURE

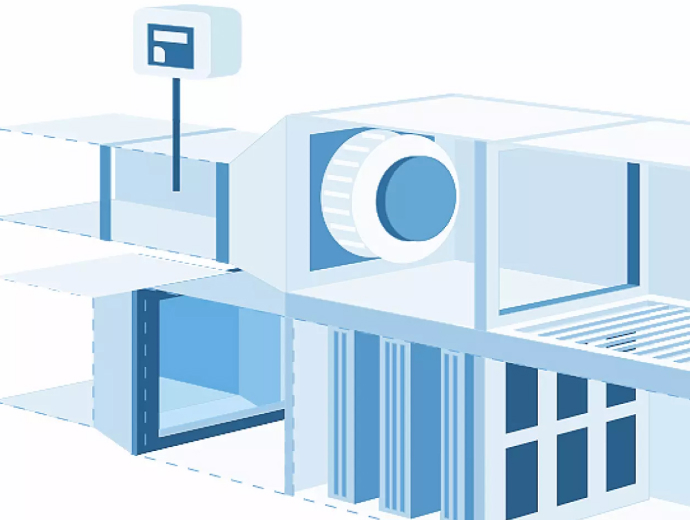

Differential pressure measurement is primarily

intended for monitoring the proper functioning of

air handling units (AHUs). It is especially

concentrated at the level of air filters and ducts,

where the differential pressure allows the flow

rate of air flows to be calculated.

The filters integrated into the AHUs become

clogged more or less quickly depending on their

filtering power. Constant monitoring is

particularly essential for HEPA and ULPA

antibacterial filters.

Measuring the differential pressure before and

after a filter makes it possible to assess its

clogging and anticipate its replacement as part

of a preventive maintenance plan. This

anticipation consists of scheduling maintenance

interventions at the right time, so as to reduce or

avoid downtime.

Historically specialized in pressure

measurement, Sauermann offers all possible

solutions in the field: connected digital pressure

gauges or liquid column pressure gauges. The

first digital solution allows values to be recorded

over time and remotely, with an audible and

visual alarm, and an integrated display on certain

models. The second analog solution is

particularly resilient because it is completely

autonomous: it does not require energy to

operate, and benefits from record durability.

AIR SPEED

AND FLOW

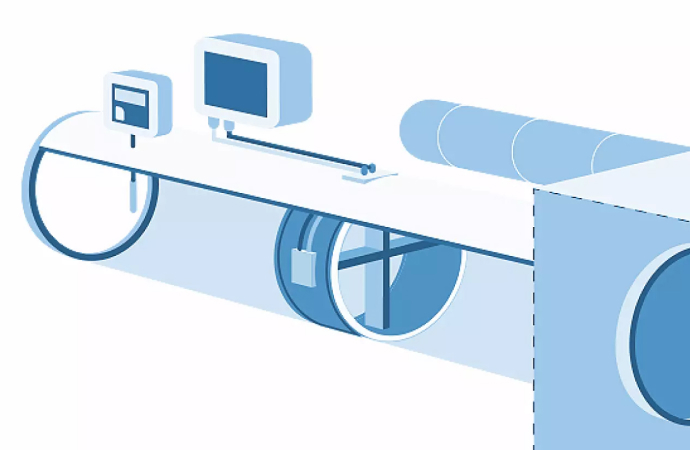

In the field of air conditioning, monitoring air

speed and flow is essential to verify proper air

circulation within a building. This measurement is

particularly important to check that the air

renewal rate is sufficient in the different areas

concerned.

Air renewal makes it possible to maintain rooms

in a constant climate, in particular to compensate

for the heat production of certain equipment

(machines, power supplies, microcomputers,

etc.). The evacuation of cold, or of chemical

substances released by certain products is just

as important, depending on the places

concerned.

This is why Sauermann offers very advanced

solutions for monitoring and recording the speed

and flow of air in ventilation ducts, both inlet and

exhaust. To calculate in real time the volumes of

air exchanged in ventilated zones, Sauermann

offers a recognized solution: DEBIMO wings.

CARBON DIOXIDE

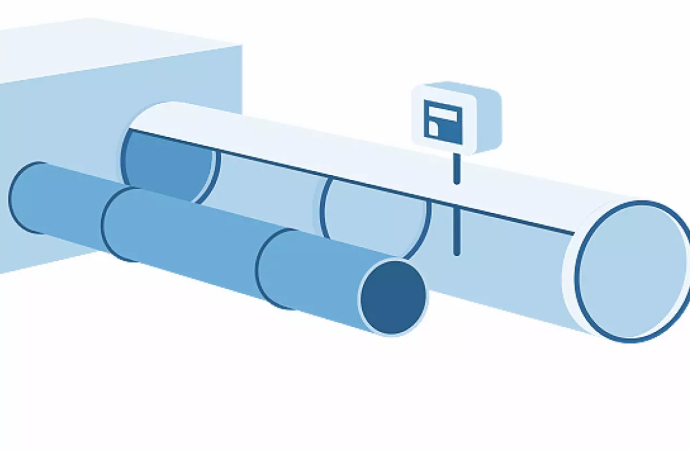

The concentration of CO2 in indoor air is the

preferred indicator of indoor air quality and

therefore of the air change rate (Air Change Rate

or ACR). It is therefore a measure of choice for

evaluating the overall and final efficiency of a

building's air conditioning system.

CO2 concentration is measured quickly and in

real time, but requires high-end CO2 sensors to

provide reliable results. Sauermann uses the

most reliable technology in the field, with NDIR

(non-dispersive infrared) sensors, and

instruments calibrated internally within the

company's laboratories.

Today, measuring CO2 levels is no longer just

reserved for the most sensitive buildings. It is

strongly recommended in all places open to the

public, particularly schools and offices. A CO2

level of 800 to 1000 ppm is currently

the subject of a scientific consensus to

demonstrate sufficient air renewal to reduce the

concentration of bacteria and viruses in

suspension, in order to mitigate the risks of

biological contamination.

PRODUCTS AND ACCESSORIES

-

Si-CPE 320

Si-CPE 320Sauermann의 Si-CPE320은 KIMO CPE 310의 진화된 모델입니다. 이 트랜스미터는 클린룸 환경에 최적화되어 작업 환경을 방해하지 않는 세련된 디자인의 매립형 설치 제품 입니다. 고급 스테인레스 스틸 방수 전면 패널과 통합된 터치 스크린을 갖추고 있어 사용자 편의성을 높였습니다. Si-C320과 동일한 고급 기술을 채택하여 최신의 신뢰성과 정확성을 제공하며, 측정 데이터는 Sauermann Control 애플리케이션/소프트웨어를 통해 효과적으로 기록하고 다운로드할 수 있습니다. Si-CPE320: 무선 통신 모듈(옵션) Si-CPE320-W: 통합형 무선 통신 모듈

Read More -

CP 210-R

CP 210-RKIMO CP 210-R 설치형 차압 트랜스미터 입니다. 압력 ±100Pa, ±1000Pa, ±10000Pa 차압 및 온도 2개의 측정값을 디스플레이 할 수 있으며, 클린룸, 병원, 제약 등 다양한 산업 환경 분야에 적용됩니다. SQR/3 옵션을 추가하여 피토관 또는 데비모 블레이드 등을 연결하여 풍속/풍량 값을 측정합니다. 측정범위: - CP211: -100 ~ +100 Pa - CP212: -1,000 ~ +1,000 Pa - CP213: -10,000 ~ +10,000 Pa

Read More -

TH 110

TH 110KIMO의 TH 110은 습도와 온도를 측정하는 설치형 트랜스미터 입니다. 상대습도의 측정범위는 5 ~ 95 %RH이며, 온도의 측정범위는 표준형과 대기형 모델은 0 ~ +50 °C, 덕트형과 프로브형 모델은 -20 ~ +80 °C 입니다. 간편한 사용법과 함께 안정적인 성능을 자랑하며, 사용자가 쉽게 데이터를 수집하고 모니터링 할 수 있도록 지원합니다.

Read More -

TH 210-R

TH 210-RKIMO의 TH 210-R은 습도와 온도를 측정하는 설치형 트랜스미터 입니다. 상대습도의 측정범위는 모델 종류에 관계없이 0 ~ 100 %RH 로 동일하며, 온도의 측정범위는 대기형 모델과 폴리카보네이트 프로브형 모델은 -20 ~ +80 °C, 스테인레스스틸 프로브형 모델은 -40 ~ +180 °C 입니다. 다양한 산업 및 연구 환경에서 신뢰성 있는 데이터를 제공하여 프로세스 모니터링과 실험실 작업에 필수적인 역할을 합니다.

Read More -

TM 110

TM 110KIMO의 TM 110은 설치형 온도 트랜스미터 입니다. 온도 0 ~ 50 °C, -20 ~ 80 °C, -100 ~ 400 °C 대기 및 기밀형 모델로 0 ~ +50 °C, 덕트형 모델로 -20 ~ +80 °C, Pt100 터미널 블록형 모델로 -100 ~ +400 °C 측정합니다.

Read More -

PST

PSTKIMO의 PST는 측정하고, 소리 및 시각 알람, 접점 신호를 발생시키는 설치형 스위치 입니다. 압력 ±100 Pa, ~±2,000 mbar, 접점 RCR relay output 설정 압력 범위에서 전기적 접점을 활성화합니다.

Read More -

CP 110

CP 110KIMO CP110 시리즈 설치형 차압 트랜스미터 입니다. CP111 / 112 / 113 : -100/+100 Pa ~ -10,000 / +10,000 Pa 측정 CP114 / 115 : -500/+500 mbar ~ -2,000/+2,000 mbar 측정

Read More -

MG Series

MG SeriesKIMO의 경사형 액주형 마노미터 MG는 밀도 0.87인 AWS.10 시약을 사용합니다. 공기 또는 가스의 압력, 감압, 차압의 미세한 변화를 측정합니다.

Read More

-

TJ series

TJ seriesKIMO의 수직 액주형 마노미터 TJ 시리즈는 범위 내의 공기 및 가스의 압력, 감압 또는 차압의 변화를 측정합니다. (AWS.10 또는 VOLT.1S 등 사용되는 마노미터 시약에 따라 달라집니다.)

Read More -

CP 25

CP 25CP 25 경사형 액주 마노미터는 공기 또는 가스의 미세한 압력 변화, 감소 또는 차압을 측정합니다. 도장 부스의 필터 막힘을 확인하는 데 특별히 설계되었습니다.

Read More -

CTV 110

CTV 110KIMO의 CTV 110은 풍속과 온도를 측정하는 설치형 열선 풍속 트랜스미터 입니다. 측정범위는 0 ~ 30 m/s, 0 ~ 50 °C의 풍속과 온도를 측정합니다. HVAC 시스템, 클린룸, 산업 공정 모니터링 등 다양한 응용 분야에서 중요한 역할을 합니다.

Read More -

CO 110

CO 110KIMO의 CO 110은 CO(일산화탄소)를 측정하는 설치형 트랜스미터 입니다. CO센서(전기화학 센서)를 통해 무색/무취의 일산화탄소를 측정할 수 있습니다.

Read More -

압력모듈

압력모듈KIMO의 압력 측정모듈은 두 개의 압력 입력과 한 개의 써머커플 입력으로 구성됩니다. 5가지 모델이 사용 가능합니다.

Read More

EXPERT CORNER

- INsights News

OUR EXPERTISE

-

- More than 800 m2

of laboratories - Our experts ensure the adjustment and

calibration of our measuring instruments.

- More than 800 m2

-

- After-sales service

within our production lines - Our technicians carry out the maintenance

and repair of your devices.

- After-sales service

-

- More than

20 patents filed - Including our oscillating piston technology

for pumps and our folding frame system

for the DBM 620 flow meter.

- More than